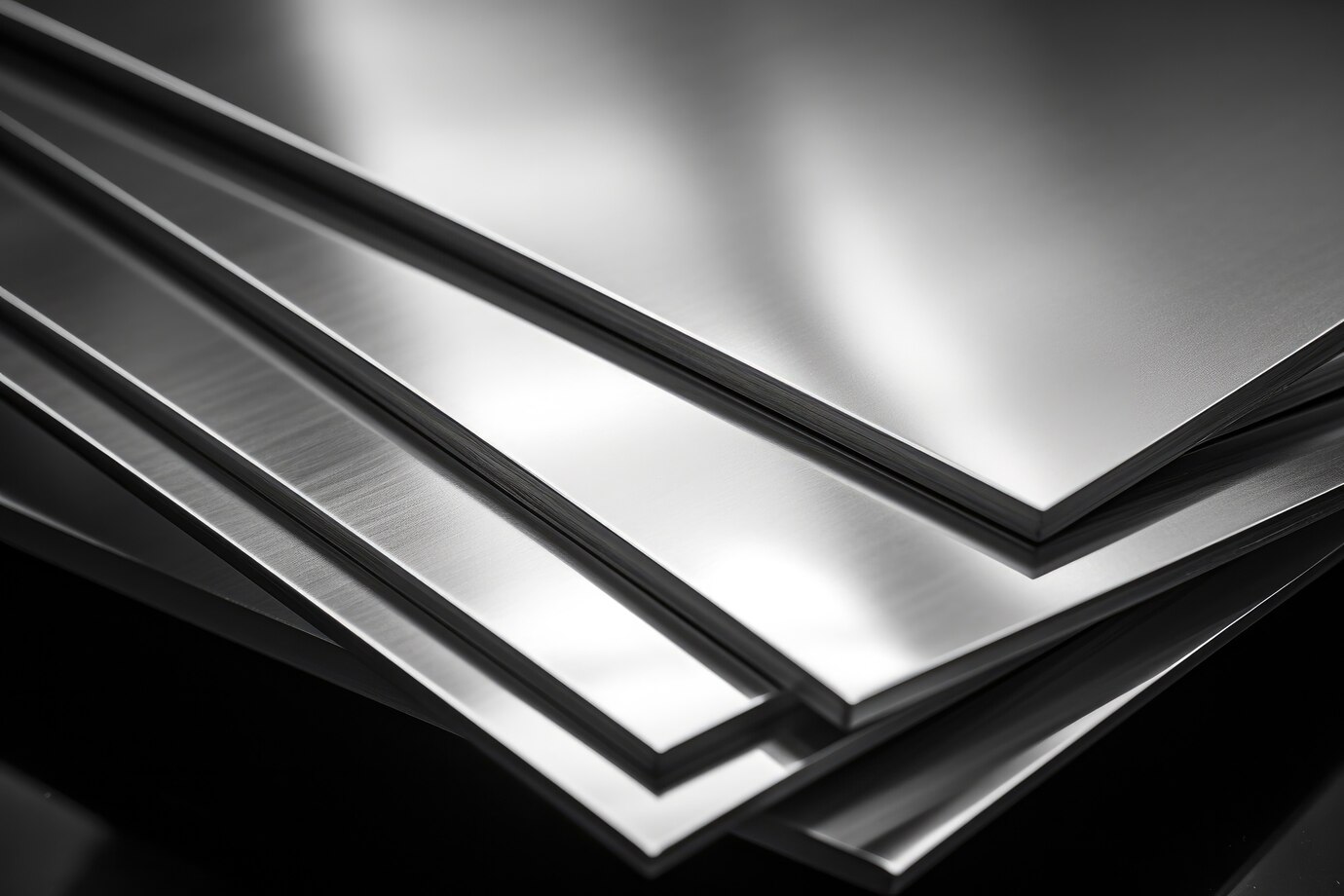

VIMCO Steel Industries takes pride in being a prominent name in the industry, specializing in the production of a diverse range of premium-quality Aluminium Alloy Semi-finished Products including Rods, Tubes, Bus Bars, Strips, Plates, Wires, Pipes, Sheets, and Circles. Our advanced facilities and adaptable processes empower us to fulfill specific product needs and precise dimensional requirements.

VIMCO Steel Industries is a trusted Manufacturer, Supplier, and Exporter of Aluminium Alloy Sheets, Plates, Coils, Seamless Pipes, Railing Pipes, as well as Welded and ERW Pipes & Tubes. Our commitment to excellence ensures products tailored to the highest standards of engineering and craftsmanship.

|

Series |

Primary Alloy |

Key Properties |

|

1000 |

Pure Aluminium (99%) |

Exceptional corrosion resistance, low strength, easy to work with, excellent conductivity, non-heat-treatable. |

|

2000 |

Copper Alloyed |

Provides increased strength and hardness, improves machinability, and is heat-treatable. |

|

3000 |

Manganese Alloyed |

Enhances moderate strength, offers good formability, and is non-heat-treatable. |

|

5000 |

Magnesium Alloyed |

Delivers moderate to high strength with excellent corrosion resistance; non-heat-treatable. |

|

6000 |

Magnesium-Silicon Alloyed |

Improves strength, formability, and corrosion resistance; heat-treatable. |

|

7000 |

Zinc Alloyed |

Provides maximum strength and is heat-treatable. |

|

ALLOY |

EQUIVALENT |

COPPER |

MAGNESIUM |

SILICON |

IRON |

MANGANESE |

*OTHERS |

REMARKS |

|||||

OLD |

NEW |

U. S. A. |

MIN. |

MAX. |

MIN. |

MAX. |

MIN. |

MAX. |

MAX. |

MIN, |

MAX. |

MAX. |

|

1 C |

19000 |

1100 |

– |

0.10 |

– |

– |

– |

0.5 |

0.6 |

– |

0.1 |

0.1 |

Aluminium 99.0% Min. |

– |

– |

1200 |

– |

0.05 |

– |

– |

– |

Si+Fe 1.0 |

– |

– |

0.05 |

0.1 |

Aluminium 99.0% Min. |

1 B |

19500 |

1050 |

– |

0.05 |

– |

– |

– |

0.25 |

0.4 |

– |

0.05 |

0.1 |

Aluminium 99.5% Min. |

1 E |

19501 |

– |

– |

0.04 |

– |

– |

– |

0.15 |

0.35 |

– |

0.03 |

0.1 |

Aluminium 99.5% Min. |

– |

19600 |

1060 |

– |

0.05 |

– |

– |

– |

0.25 |

0.35 |

– |

0.03 |

0.1 |

Aluminium 99.6% Min. |

H 15 |

24345 |

2014 |

3.8 |

5.0 |

0.2 |

0.8 |

0.5 |

1.2 |

0.7 |

0.3 |

1.2 |

0.5 |

– |

H 14 |

24534 |

2017 |

3.5 |

4.7 |

0.4 |

1.2 |

0.2 |

0.7 |

0.7 |

0.4 |

1.2 |

0.5 |

– |

– |

– |

2024 |

3.8 |

4.9 |

1.2 |

1.8 |

– |

0.5 |

0.5 |

0.3 |

0.9 |

0.15 |

Zn 0.25 |

N 3 |

31000 |

3003 |

– |

0.1 |

– |

0.1 |

– |

0.6 |

0.7 |

1.0 |

1.5 |

0.4 |

– |

N 4 |

52000 |

5052 |

– |

0.1 |

1.7 |

2.6 |

– |

0.6 |

0.5 |

– |

0.5 |

0.4 |

Cr + Mn = 0.5 |

N 5 |

53000 |

5086 |

– |

0.1 |

2.8 |

4.0 |

– |

0.6 |

0.5 |

– |

0.5 |

0.4 |

Cr + Mn = 0.5 |

N 8 |

54300 |

5083 |

– |

0.1 |

4.0 |

4.9 |

– |

0.4 |

0.7 |

0.5 |

1.0 |

0.4 |

Chromium up to 0.25 |

H 20 |

65032 |

– |

0.15 |

0.4 |

0.7 |

1.2 |

0.4 |

0.8 |

0.7 |

0.2 |

0.8 |

0.4 |

**Cr = 0.15 – 0.35 |

– |

– |

6061 |

0.15 |

0.4 |

0.8 |

1.2 |

0.4 |

0.8 |

0.7 |

– |

0.15 |

0.4 |

Chromium 0.04 to 0.35 |

H 9 |

63400 |

6063 |

– |

0.1 |

0.4 |

0.9 |

0.3 |

0.7 |

0.6 |

– |

0.3 |

0.4 |

– |

– |

– |

6066 |

0.7 |

1.2 |

0.8 |

1.4 |

0.9 |

1.8 |

0.7 |

0.6 |

1.1 |

0.4 |

– |

– |

64423 |

– |

0.5 |

1.0 |

0.5 |

1.3 |

0.7 |

1.3 |

0.8 |

– |

1.0 |

– |

– |

9 1E |

63401 |

6101 |

– |

0.05 |

0.4 |

0.9 |

0.3 |

0.7 |

0.5 |

– |

0.03 |

0.1 |

– |

H 30 |

64430 |

6351 |

– |

0.1 |

0.4 |

1.2 |

0.6 |

1.3 |

0.6 |

0.4 |

1.0 |

0.3 |

– |

– |

– |

6082 |

– |

0.1 |

0.6 |

1.2 |

0.7 |

1.3 |

0.5 |

0.4 |

1.0 |

0.3 |

Chromium up to 0.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Zn 5.7 – 6.7 |

– |

– |

7018 |

– |

0.2 |

1.2 |

1.4 |

– |

0.35 |

0.4 |

0.05 |

0.5 |

0.15 |

Zn 3.5 – 4.5 |

– |

– |

7020 |

– |

0.2 |

1.0 |

1.4 |

– |

0.35 |

0.4 |

0.05 |

0.5 |

– |

Zn 4.00 – 5.00 |

– |

– |

7150 |

1.9 |

2.5 |

2.0 |

2.7 |

– |

0.4 |

0.15 |

– |

0.1 |

– |

Zn 5.1 – 6.1

|

– |

– |

7175 |

1.2 |

2.0 |

2.1 |

2.9 |

– |

0.15 |

0.2 |

– |

0.1 |

– |

Zn 5.1 – 6.1

|

– |

– |

7475 |

1.2 |

1.9 |

1.9 |

2.6 |

– |

0.1 |

0.12 |

– |

0.06 |

– |

Zn 5.2 – 6.2

|

|

INDIA |

U.S.A. |

BRITAIN |

CANADA |

GERMANY |

RUSSIA |

I.S.O. |

FRENCH |

|

|

New IS |

Old IS |

(A.A.) |

(B.S.) |

(DIN) |

– |

– |

– |

|

19501 |

1E |

1050(E.C.) |

1E |

C 1S |

E-Al 99.5 |

– |

Al-99.5 |

1050A |

19500 |

1B |

1050 |

1B |

1S |

A-99.5 |

– |

– |

– |

19600 |

– |

1060 |

– |

– |

– |

– |

Al-99.7 |

– |

19700 |

– |

1070 |

– |

– |

Al-99.7 |

– |

Al-99.8 |

– |

19800 |

1A |

1080 |

1A |

– |

– |

– |

Al-99.0 |

1200 |

19000 |

1C |

1100 |

1C |

2S |

Al-99.0 |

AD |

Al-Cu-6 Bi Pb |

2011 |

– |

– |

2011 |

FC1 |

28S |

Al-Cu-Bi-Pb |

– |

– |

– |

24345 |

H15 |

2014 |

H15 |

B26S |

Al-Cu-Si |

AK |

Al-Cu-4Mg Si |

– |

24534 |

H14 |

2017 |

H14 |

17S/16S |

– |

D1 |

Al-Cu-4Mg 1 |

2024 |

– |

– |

2024 |

– |

24S |

Al-Cu-Mg.2 |

– |

AlCu-4PbMg |

2030 |

– |

– |

2030 |

– |

– |

Al-Cu-Mg-Pb |

– |

Al-Cu2-Mg1.5-Ni |

2618 |

– |

– |

2618 |

2618 |

– |

– |

– |

A-Mn 1 |

3003 |

31000 |

N3 |

3003 |

N3 |

3S |

Al-Mn |

A-Mn |

Al Mn 1 Mg 1 |

3004 |

– |

– |

3004 |

– |

Al-Mn.1-Mg.1 |

Al Mn 1 Mg 0.50 |

3005 |

||

– |

– |

3005 |

– |

Al-Mn.1-Mg.0.50 |

Al-Si5 |

4043 |

||

43000 |

N21 |

4043 |

N21 |

33S |

Al-Si-5 |

AK |

– |

– |

46000 |

N2 |

4047 |

N2 |

35S |

– |

– |

A-Mg-1 |

– |

51000 |

– |

5005 |

– |

B57S |

– |

– |

Al-Mg-2 |

5251 |

5051 |

5251 |

Al-Mg.2 Mn.0.30 |

A-Mg-2.5 |

5051 |

||||

52000 |

N4 |

5052 |

N4 |

M57S |

Al-Mg.2 |

A-Mg |

A-Mg-4 |

– |

53000 |

N5 |

5086 |

N5 |

54S |

– |

A-Mg-3 |

Al-Mg-4.5 Mn |

5083 |

54300 |

N8 |

5083 |

N8 |

D54S |

Al-Mg-4.5 Mn |

– |

Al-Mg.5 |

5356 |

55000 |

N6 |

5056 |

N6 |

A56S |

Al-Mg.5 |

– |

Al-Mg.3-Mn |

5454 |

5454 |

5454 |

Al-Mg.2.7-Mn |

– |

Al.Mg.3 |

5754 |

|||

5754 |

Al-Mg.3 |

Al-Mg-1Si Cu |

– |

|||||

65032 |

H20 |

6061 |

H20 |

65S |

Al-Mg-Si Cu |

– |

Al-Mg-Si |

– |

63400 |

H9 |

6063 |

H9 |

50S |

Al-Mg-Si 0.5 |

– |

Al-Si-1 Mg |

6081 |

64430 |

H30 |

6351 |

H30 |

B51S |

Al-Mg-Si 1 |

AV |

Al-Si-1 Mg Mn |

6082 |

6082 |

6082 |

Al-Mg-Si 1 |

– |

– |

– |

|||

64423 |

H11 |

6066 |

H11 |

C62S |

– |

– |

– |

|

62400 |

– |

6005 |

– |

C51S |

– |

– |

– |

– |

63401 |

91E |

6101 |

91E |

D50S |

E.Al.Mg.Si 0.5 |

– |

– |

– |

64401 |

– |

6201 |

– |

– |

– |

– |

– |

|

– |

– |

7020 |

7020 |

– |

– |

– |

7020 |

|

74530 |

– |

7039 |

– |

D74S |

– |

– |

3004 |

|

– |

– |

7075 |

DTD-5124 |

75S |

– |

Al-Zn 6 Mg Cu |

7075 |

|

40800 |

8011 |

– |

Al-Fe-Si |

8011 |

||||

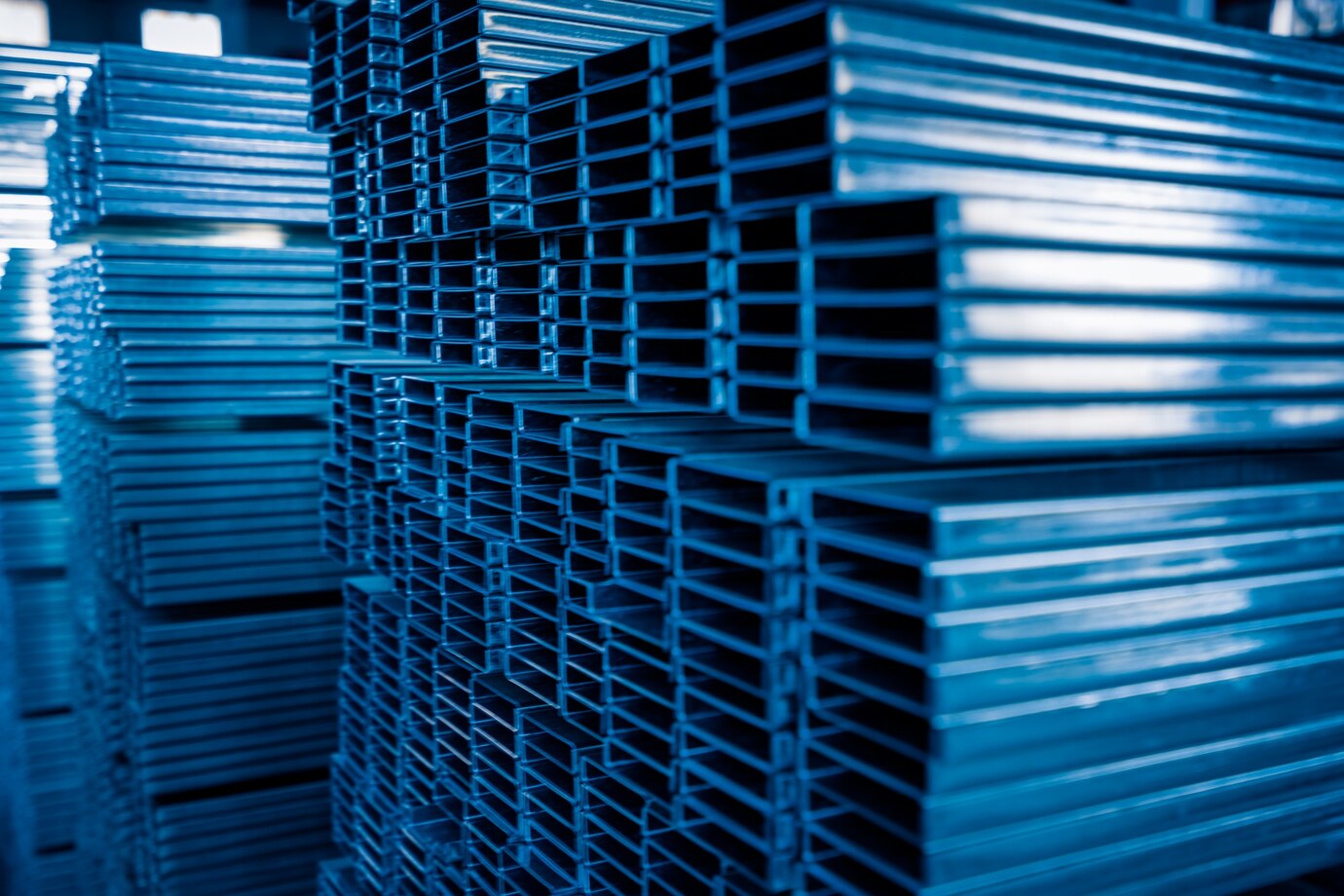

Aluminium Round Bar Grades: 6061, 6082, 5083, 5086, 5052, 6063, 7075, 1100 |

||

| Specifications | : | ASTM B221 / ASTM SB221 |

| Standards | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Available Sizes | : | Ranges from 5 mm to 500 mm |

| Diameter Options | : | 0.1 mm to 100 mm |

| Length Range | : | From 100 mm up to 3000 mm or more |

| Finishing Options | : | Includes Polished, Matte, BA Finish, Black, Bright Polished, and Rough Turned |

| Tolerances | : | H8 to H13, K9 to K12, or tailored to client needs |

| Shapes Available | : | Round, Hexagonal, Square, Rectangular, Billet, Ingots, Forged, and more |